Understanding and optimizing key production metrics is essential to staying competitive in today’s fast-paced manufacturing industry. Takt Time and Cycle Time are two metrics that are vital in streamlining processes, meeting customer demand, and boosting productivity.

But what exactly are these powerful concepts? How do they differ from one another? This article will decode the mystery behind Takt Time and Cycle Time, compare their distinct characteristics, and demonstrate how mastering them can unleash the full potential of your operations.

Buckle up – you’re about to embark on an enlightening journey that will help you better understand these essential metrics while supercharging your production process!

We’ll uncover the following:

- What is Takt Time?

- What is Cycle Time?

- Comparing Takt Time vs. Cycle Time

- Determining When To Use Each Metric For Optimal Results

- Strategies for Optimizing Takt Time and Cycle Time

- Using a Dedicated Time Tracker to Optimize Takt Time and Cycle Time

- Wrap-up: Take Control of Takt Time and Cycle Time to Improve Efficiency

What is Takt Time?

Takt time represents the maximum time allowed to produce a product to meet customer demand. Production managers use Takt time to align the production rate with the demand rate, ensuring that the manufacturing process is neither too slow nor too fast.

For instance, if you have eight hours of production time and four orders for your product, then your Takt Time would be two hours per unit – meaning that each unit needs to be completed within two hours to keep up with customer demand. Takt Time helps organizations achieve their desired output while ensuring they don’t overproduce or fall short of meeting customer demand.

Calculation And Factors Affecting Takt Time

Calculating Takt Time is relatively simple. It involves dividing the available production time by the customer demand. The formula for Takt Time is:

Takt Time = Net Available Production Time / Customer Demand

The available production time is the total working time minus any planned downtime, such as breaks, maintenance, or meetings. On the other hand, customer demand represents the number of units customers require during the specified time frame.

It’s essential to consider factors that can affect Takt Time, such as:

- Variations in demand,

- Production capacity, and

- Resource availability.

Adjusting Takt Time as needed helps maintain a smooth production flow and consistently meets customer requirements.

Takt Time for Production Planning and Meeting Customer Demand

Takt time helps production managers make more informed decisions when planning and scheduling production. Here are some ways in which Takt time helps streamline production:

- Aligning production rate with customer demand: Takt Time ensures that the manufacturing process operates at a pace that matches customer requirements, preventing overproduction or stockouts.

- Optimizing resource allocation: Takt Time helps determine the number of workstations, equipment, and staff needed to meet demand, enabling efficient use of resources and minimizing waste.

- Identifying bottlenecks and areas for improvement: By monitoring Takt Time, manufacturers can identify and address process inefficiencies, helping to streamline production and increase overall efficiency.

- Establishing a consistent production schedule: Takt Time provides a clear target for output, allowing manufacturers to create achievable production schedules that balance customer demand with available resources.

- Fostering continuous improvement: Takt Time is a foundation for implementing Lean Manufacturing and other improvement methodologies, driving ongoing enhancements in production processes and overall operational effectiveness.

What is Cycle Time?

While Takt time refers to the rate at which products must be produced to meet customer demand, cycle time is the total amount of time it takes to produce a single unit. In other words, cycle time measures how quickly you can move from one product to another.

In a manufacturing context, Cycle Time has two distinct meanings:

- First, it denotes the total duration of a specific process or operation;

- Second, it reflects the overall throughput for an entire production line (i.e., how many units are produced per hour).

Cycle Time is a key performance indicator (KPI) since it reveals how efficiently resources are used and allows for better decision-making.

Calculation and Factors Affecting Cycle Time

Calculating Cycle Time involves dividing the total production time by the number of units produced during that period. The formula for Cycle Time is:

Cycle Time = Total Production Time / Number of Units Produced

Several factors can affect Cycle Time, such as:

- Process complexity,

- Machine performance,

- Worker skill level, and

- The availability of raw materials.

Understanding these factors and addressing any issues can help reduce Cycle Time and improve the overall efficiency of the production process.

Role of Cycle Time in Process Efficiency

Manufacturers can quickly spot deviations from their desired output rate by monitoring and analyzing cycle times over time. Here are some ways Cycle time can help you optimize the production process:

- Balancing workloads: Analyzing Cycle Time data can reveal workload imbalances between workstations or production lines, allowing managers to redistribute tasks or resources to improve efficiency.

- Enhancing productivity: By reducing Cycle Time, manufacturers can increase the throughput of their production processes, leading to higher output and improved productivity.

- Reducing lead time: Optimizing Cycle Time helps minimize the time it takes to produce and deliver finished products to customers, enhancing customer satisfaction and reducing inventory holding costs.

Tracking and analyzing Cycle Time data can provide valuable insights into the effectiveness of process improvement initiatives, enabling manufacturers to make data-driven decisions and continuously refine their operations.

Comparing Takt Time vs. Cycle Time

Now that we better understand Takt Time and Cycle Time, let’s compare their key differences.

At its core, Takt Time is an ideal rate at which products must be produced to meet customer demand – it reflects the speed at which production needs to occur. On the other hand, Cycle Time measures how long it takes for one unit to be completed from start to finish.

Therefore, Takt time focuses on meeting market requirements while cycle time emphasizes efficiency within each process step or operation. It’s also important to note that Takt Times are calculated based on customer demand, while cycle times are based on the actual time it takes to produce one unit.

Determining When To Use Each Metric For Optimal Results

While Takt Time and Cycle Time are both valuable metrics, their utility depends on the specific goals and challenges of the manufacturing process:

Use Takt Time when:

- Establishing production targets to meet customer demand

- Allocating resources, such as staff, equipment, and workstations

- Planning production schedules and setting priorities

Use Cycle Time when:

- Analyzing process efficiency and identifying bottlenecks

- Evaluating the effectiveness of process improvements or Lean Manufacturing initiatives

- Balancing workloads and reducing lead time

In many cases, using both Takt Time and Cycle Time in tandem will yield the best results. They provide complementary insights that can help manufacturers optimize their operations and achieve a competitive advantage.

Strategies for Optimizing Takt Time and Cycle Time

A well-planned and optimized Takt Time and Cycle Time strategy is essential for optimizing the production process and achieving higher efficiency. Here are some strategies you can use to ensure that your operations hit peak performance:

- Analyze processes to identify areas of inefficiency. Using data analysis tools, map out workflows and pinpoint any bottlenecks or points of delay.

- Focus on reducing variation in each step of the workflow through standardization. This will help create a consistent output rate crucial for maintaining balance throughout production.

- Utilize automation to eliminate tedious manual tasks and reduce time spent on repetitive tasks. Automation can also help reduce human error and improve accuracy.

- Implement Lean Manufacturing principles to identify and eliminate waste from the production process continuously. This will help ensure that all resources are used effectively and efficiently for maximum output.

- Monitor Takt Time and Cycle Time metrics regularly to quickly identify any anomalies or issues before they become significant problems.

Using a Dedicated Time Tracker to Optimize Takt Time and Cycle Time

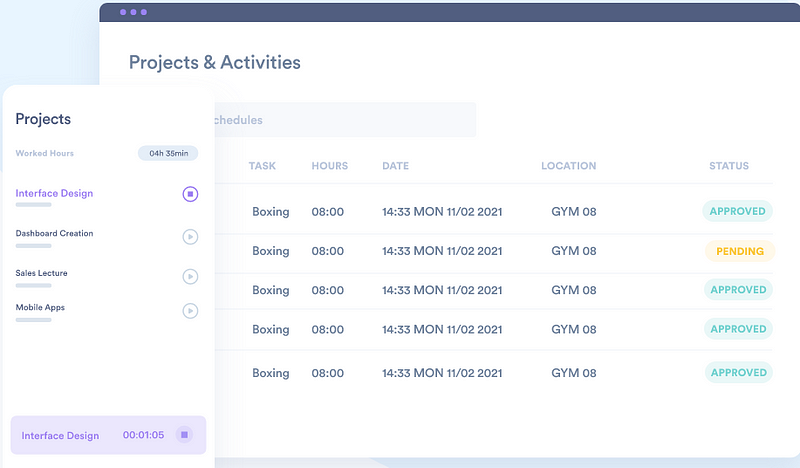

One of the best ways to optimize Takt Time and Cycle Time is to use a dedicated time-tracking system like Day.io. A time tracker will provide accurate, up-to-date information that you can use to monitor performance metrics, identify areas of improvement, and adjust plans accordingly.

Time trackers also allow for better workforce management by automatically recording employee timesheets and calculating payroll. This helps ensure that all employees are paid accurately for their work while avoiding overpayments or underpayments due to human error.

Using Day.io, you can:

- Monitor Takt Time and Cycle Time performance in real-time

- Analyze employee performance data to identify areas of improvement

- Track job costs and compare them against budgeted amounts

- Generate reports on production time, output, labor costs, and more.

Day.io also integrates with other management systems like ERP software to comprehensively overview your operations. With these features, you can optimize Takt Time and Cycle Time while ensuring processes run smoothly.

Wrap-up: Take Control of Takt Time and Cycle Time to Improve Efficiency

Understanding the concepts of Takt Time vs Cycle Time, along with their differences, is essential for anyone looking to optimize their manufacturing processes. By delving into the metrics of Takt time vs. Cycle time, you can identify performance bottlenecks, maximize resource utilization and create a production process that meets customer demands.

To help you master this critical skill set, sign up for Day.io: a dedicated time tracker to monitor Takt Time and Cycle Time. Day.io provides valuable data and insights to drive continuous improvement in your manufacturing processes – so don’t let the complexities of Takt Time and Cycle Time hold you back any longer! Take control of your production process today with Day.io.